The Problem:

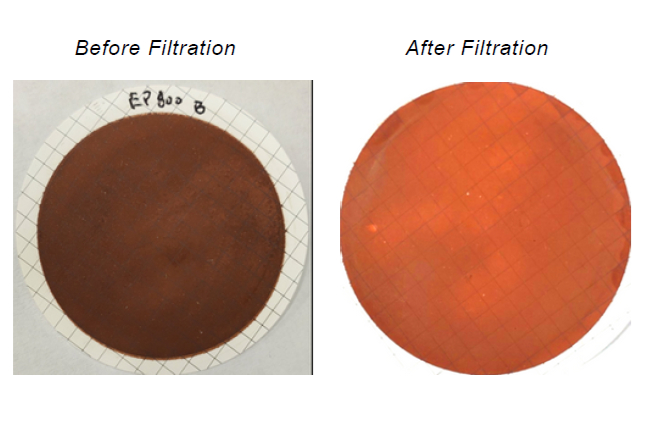

A metal processing facility experienced a failure in one of the components on a large Central Gear Oil System. This failure severely contaminated their 4,500-gallon custom blend EP-800 Gear Lubricant System with metal particulate. The oil was in pristine condition but needed to have the mass amounts of metal fines removed. The viscous nature (800 CST at 40 C) of the oil posed a challenge for efficiently removing this particulate.

The Solution:

"After conversations with the Oil Filtration Systems team, we decided to rent a 30 GPM Skid Unit containing an oversized heater bank and multiple stages of filtration. This allowed us to effectively heat the oil to reduce the viscosity and remove the particulate. The job went wonderfully well and we are grateful for the expertise and great support we always receive from the OFS Team."

- Chris Higgins, CLS, OMA-I | Director of Services | Kimbro Oil Company - Nashville